I-COMPOSITE

COMPOSITE,

IFIBER YEGLASI,

Incazelo

UHLOBO LOKUQHUBEKA LWEBHANDE ELIQHUBEKAYO UMUGQA WOKUKHIQIZA OKUQHUBEKAYO USESETSHENZISWA UKUKHIQIZA IFIBER EQINISEKILE I-THERMOPLASTIC UNIDIRECTIONAL PREPREG BELT LAMINATE, EFANELE UKHIQIZWA OKUNINGI KWE-THERMOPLASTIC COMPOSITE COMPOSITE ukuze kusetshenziswe inhlanganisela ye-fiber ehlukahlukene/engasetshenziselwa i-fiber COMPOSITE ehlukahlukene.I-Thermoplastic unidirectional prepreg laminate;Kuyipuleti eliqinile elakhiwe nge-fiber eqhubekayo eqiniswe ibhande le-prepreg le-thermoplastic unidirectional.Umbala ojwayelekile umhlophe nomnyama.Ikakhulukazi esetshenziswa ku-fiber eqhubekayo eqinisa izixazululo ze-thermoplastic engasindi njengamaphaneli e-thermoplastic composite honeycomb;Ibhodi lesiketi seloli;Ikhava yebhethri yemoto kagesi;Ibhodi lomugqa wesitsha;Amashede ezitimela, amabhodi ezimoto nokunye

Ishidi le-CFRT liyishidi eliyinhlanganisela ye-thermoplastic elenziwe ngendwangu yendlela eyodwa ye-CFRT ngokuhambisana no-0°,45°,-45°,90° kanye nenhlanganisela eyodwa noma ngaphezulu ngemva kokucindezela okushisayo nokubanda.Ingase futhi ihlanganiswe nezinye izinto eziyinhloko ezisebenza kahle, njengebhodi lezinyosi, i-polyurethane foam, i-balsa balsa, ibhodi eliqinile elicindezelwe ngokhuni, njll., noma ngezinto ezingezona ezilukiweyo ukuze kwakhiwe ibhodi elisha eliyinhlanganisela yesangweji.

Izinzuzo: I-fiber eqhubekayo inikeza amandla aphezulu nokuqina;Ukusebenza okuhle kakhulu kwe-interlaminar shear, amandla omthelela aphezulu;Imodi yokubeka, ukujiya, ukuqinisa uhlobo lwezinto ezibonakalayo kanye nokuqukethwe kwevolumu ye-fiber yeshidi kungenziwa ngendlela oyifisayo ukuhlangabezana nezidingo zamakhasimende ezimbonini ezahlukene;Indawo yomkhiqizo ngaphandle kokusanhlamvu kwendwangu;Ukumelana nokugqwala, ukumelana nesikhutha, kulula ukuhlanza, akuthinteki abahlanzi bamakhemikhali;Iyashisela, kulula ukuyisika, ukuyifaka nokukhanda;Kungaba ukubumba okucindezelayo okushisayo, umjikelezo wokwakha ufushane;Ingakwazi ukufaka esikhundleni se-thermosetting ingilazi yepulasitiki eqinisiwe, i-aluminium neshidi lensimbi engagqwali, futhi ifanele izinto zokuhamba ezingasindi;Ukuvikelwa kwemvelo okuluhlaza, okugaywa kabusha, ukuthuthukiswa okusimeme.

Imodeli kanye nepharamitha

| Imodeli | SPX1700 | SPX2300 | SPX3000 | SPX3400 |

| Ububanzi bebhande(mm) | 1700 | 2300 | 3000 | 3400 |

| Ububanzi obusebenzayo(mm) | 800-1550 | 1450-2000 | 2000-2750 | 2300-3050 |

| Ubude bokushisa(mm) | 1500-3000 | 1500-3000 | 2500-4000 | 2500-4000 |

| Imodi yokushisa | Ukushisisa ngogesi | Ukushisisa ngogesi Ukushisa kwamafutha | Ukushisisa ngogesi Ukushisa kwamafutha | Ukushisisa ngogesi Ukushisa kwamafutha |

Umshini wokucindezela ojwayelekile

Umshini wokucindezela ojwayelekile (Isisindo semikhiqizo:0-1600 GSM)

Umshini wokucindezela okuphezulu

Umshini wokucindezela ophezulu (Isisindo semikhiqizo: 1600-2200 GSM)

Ihhavini

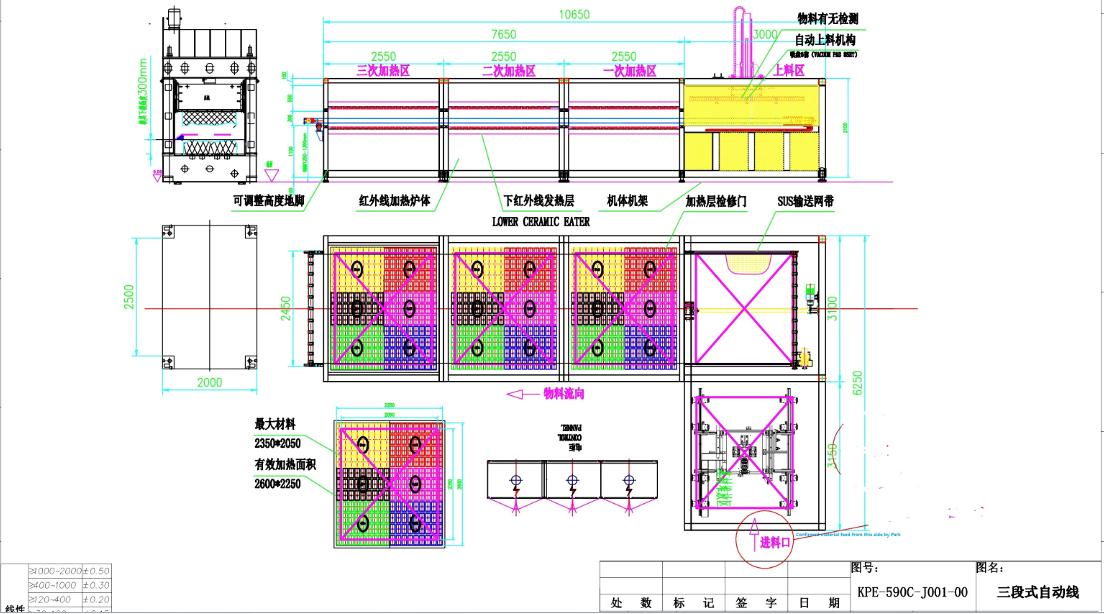

Lo mugqa ozenzakalelayo ungacubungula kalula amaphasela nemikhiqizo yeshalofu ukuze unikeze izinhlobo ezahlukene zamamodeli ezimoto.Iphethwe ngokufaka kwe-PLC.

1. Isiteshi sokulayisha impahla esizenzakalelayo siqukethe izingxenye ezimbili zokulayisha.Kuncike kumadivayisi we-KEC we-needlepunch nezinkomishi ze-vacuum ukwenza imisebenzi yokukhetha nendawo ukuze ivumelane nezinhlobo ezahlukene zezinto.Ukushintsha kwezinto ezizenzakalelayo kuyasiza ekuthuthukiseni ukusebenza kahle.

2. I-heater yokuxhumana inikeza ukusebenza kahle okuphezulu kanye nokuma okunembile kwezinto, okusiza kakhulu ukufeza ukushisisa okusheshayo nokuthutha izinto.

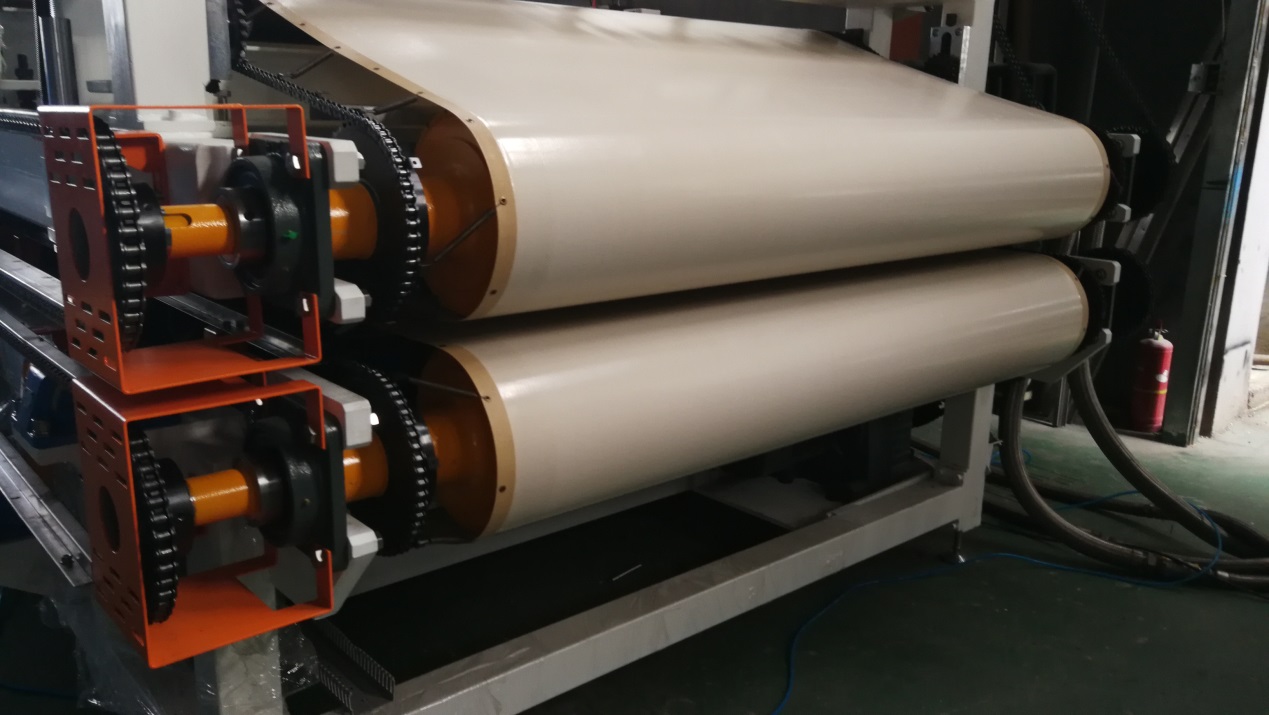

3. I-conveyor mechanism isebenza ngamabhande e-Teflon azungezayo aye phezulu naphansi ukuze agweme okunamathelayo kumapuleti okushisisa aphezulu naphansi, ahlala ehlanzekile futhi asuse amabala kalula.

4. Umshini okhethekile womshini we-hydraulic wefreyimu olungiselelwe iplatifomu enkulu yokusebenza ifaniswe nesistimu ye-mold clamping esheshayo ukuze isikhunta singashintshaniswa ngokushesha futhi sivikelwe yi-button-push eyodwa.

5. Ngemuva kokuthi izindwangu ezigoqayo zilayishiwe, zinganqunywa futhi zihanjiswe ku-mouldingpress ngokuzenzakalelayo.Ngaleso sikhathi, isistimu yokubona impahla enesici ingasika ngokuzenzakalelayo ingxenye enephutha yamaroli bese iyithumela ebhokisini likadoti.

6. Isilawuli kude, ukuphathwa kwefekthri okuhlakaniphile nokuqapha kwevidiyo yokukhiqiza kungafinyelelwa kabanzi ngokususelwe kulo mugqa.