PVC CPVC Soild Extrusion Pipe

Izixazululo Zokonga Izindleko

1. Ukwengezwa Okuqondile - CaCO3

2. Amayunithi okulawula udonga (izikena)

3. I-Automatic Thermal Centering (ATC)

4. Amasistimu we-Gravimetric (RGS)

Ukwengezwa Okuqondile kwe-SUPX - RDA

I-RDA iqinisekisa ukuthi ukwengezwa kwezinto ku-pvc powder kuzokwenziwa ngendlela eqondile nengaguquguquki.Iyunithi ye-RDA ifakwe ku-extruder ukuze kufakwe umthamo njalo wezinto eziphathwayo okunzima ukuzibamba endaweni yezimboni.Amanani aphezulu e-CaCO3 angengezwa ngaphandle kwenkinga yokuhlukaniswa.Amayunithi okudosa amaningi ezithasiselo angafakwa anikeze ukuguquguquka okuphelele kokukhiqizwa.

Izinzuzo zezinhlelo ze-RDA

• Akukho ukuhlukaniswa kwe-CaCO3 ne-PVC ngesikhathi sokuthutha.

• Ipayipi elibushelelezi.

• Ukuhlanganisa ukonga amandla.

• Ukwenyuka kokuguquguquka komugqa we-extrusion (ukwakheka kwesisekelo).

• Ukwengezwa kwe-Gravimetric kwezithasiselo.

• Imiphumela ephezulu ngamanani aphansi okwenqaba.

Amayunithi Okulawula Udonga - Izikena

Ukulawula ubukhulu bepayipi ngesikhathi sokukhiqiza kuyisici esibalulekile sokugcina ipayipi ekucacisweni okuthandwayo.izikena ziyakwazi ukukala ukushuba kodonga lwamapayipi nobubanzi.Izinhlobonhlobo zezikena ezinezici ezihlukahlukene ziyatholakala, ezimboza osayizi bamapayipi ukusuka ku-10-1600 mm (1/2" - 60") ububanzi.

Izinzuzo Zezikena zethu:

• Ukuqina kodonga olusemgqeni okuqhubekayo kanye nesilinganiso sobubanzi

• Ukulawula ukujiya kodonga (ukunciphisa isisindo esiningi)

I-Automatic Thermal Centering - i-ATC

I-ATC yenza kube nokwenzeka ukulawula ukusatshalaliswa kokuqina kodonga.I-ATC ingalungisa umehluko ekujikeni kodonga futhi ngaleyo ndlela yehlise isikhathi sokuqalisa umugqa wokukhiqiza, ukukhuluphala ngokweqile kwepayipi kanye nezilahlwa zempahla.

I-Gravimetric System - RGS

Ingxenye eyinhloko ye-RGS i-hopper yokukala.Ngemva kokugcwaliswa, okubalulekile kugeleza kusuka ku-hopper enesisindo kuya ku-extruder. Ukuncipha kwesisindo ngeyunithi ngayinye yesikhathi kulingana nokuthathwa kwempahla kwe-extruder.Ukukhishwa kwe-extruder okutholiwe kuqhathaniswa nenani eliyireferensi elimisiwe futhi isistimu yokulawula izolungisa isivinini sesikulufu se-extruder (noma isivinini somthamo) ukuze ilethe okukhiphayo kuleveli oyifunayo.Lokhu kulawula kugcina okukhiphayo okuphumayo kuzinzile naphezu kokushintshashintsha kokuminyana kwenqwaba yezinto ezingavuthiwe.

Esikhundleni sokulawula okukhiphayo, isignali yokuphumayo ingase isetshenziselwe ukulawula isivinini sokudonsa.Uma kunjalo isisindo sepayipi ngemitha sigcinwa ezingeni eliqhubekayo.Lapho umugqa uhlanganisa isithwebuli se-ultrasonic, okukhiphayo okukaliwe kusetshenziselwa ukulinganisa okuzenzakalelayo kokulinganisa kwe-ultrasonic.Lokhu kuqeda izinqubo zokulinganisa ezenziwa ngesandla ezidla isikhathi.

Uhlelo Lokulawula Inqubo - PCS II

I-PCS II ngokwayo iyisistimu yokulawula engahlanganiswa neisithwebuli, i-ATC, i-RDA, ne-RGS.Uhlobo lwesithwebuli, i-ATC kanyeuhlelo lwe-gravimetric luncike kumugqa we-extrusion.

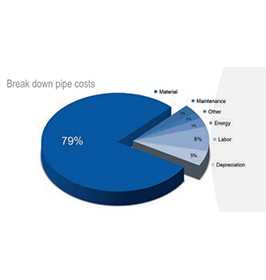

Izinzuzo zezixazululo zethu zokonga izindleko

• Imbuyiselo enhle kakhulu ekutshalweni kwezimali

• Ukuncishiswa kwesikhathi sokuqala kanye ne-scrap

• Isixhumi esibonakalayo esisebenziseka kalula sokulawula okuphelele komugqa we-extrusion

• Ukunciphisa umzimba

• Ingasetshenziswa ezintweni ezikhona.